Technology - LED Dimmer

Background

To achieve LED dimming, the LED bulb itself or the driver (power supply) must support dimming function. In other words, replacing the LED driver with a dimmable LED driver would make a non-dimmable LED lamp become a dimmable version. However, using a dimmer switch with Non-Dimmable LED lamp may somewhat reduce the brightness level. But eventually, the lamps would misbehave (flickering or even popping up at low frequency) and switch-off.

Many of the dimming technologies used for conventional sources can also work with LEDs. These include 0/1-10V analog, DALI (Digital Addressable Lighting Interface), DMX (Digital Multiplex), and other techniques that separate the dimming signal from AC Mains voltage. However, compared to Traditional Lighting, LED lighting is more complicated because not all drivers are built alike. Different circuitry means different ways of drawing power, converting it, and outputting it. Consequently, one lamp on a single dimmer might work but when several lamps are added in parallel may not dim well.

The most common phase control device is the TRIAC dimmer. NEMA estimates that there are 150 million of these installed in U.S. homes, and that these legacy devices will represent the bulk of dimming devices for replacement LED fixtures as incandescent sources are phased out. Unfortunately, the compatibility of LEDs with TRIAC dimmers is problematic. Many existing and installed dimmers are two-wire devices; that is, the same wire that provides power to the light source also conveys the dimmed voltage, or dimming signal. This can interfere with the functioning of both the LED device and the dimmer. Dimmers, particularly those with additional features such as nightlights and light level indicators, have internal circuitry that require constant, albeit minimal, power even when the light source is turned off. With incandescent, this can be done without triggering illumination of the lamps. Because LEDs don’t require much to power up, this is a little trickier for those devices, which may also flicker. Flicker, dimming, and color shift are some of the outstanding performance issues that may prompt professional and consumer wariness toward solid-state technology.

- A list of introductory articles that discuss the process and common issues related to dimming in LEDs. Lightbulbs.comLux ReviewRecommend DimmingLutron LED White PaperSpectrum.orgEere.Energy.Gov

Solution

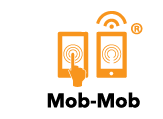

Rather than presenting a lighting solution that adds-on to existing electrical installation, our focus is in Retrofit scenario, where we can (or are only allowed to) replace existing components with our products that allow the use of existing wiring and or accessories. The Yoswit smart dimmers perform dimming function are that it be smooth, deep, and has a low risk of visible distractions or physiological effects of flicker through the dimming range when connecting to dimmable lamps, and can be switched to ON/OFF function when connecting to non-dimmable lamps through the app. The dimmer can be compatible with different lamps which include not only incandescent Lamp and Halogen Lamp, but also dimmable CFL and LED. It is flexible to change the lamp to match different light fittings anytime to meet your lighting design even after installation, without any limitation on choosing lamps from now on...

Flicker-Free Leading Edge And Trailing Edge Dimmer (Universal Dimmers)

Phase-Cut dimmer blocks the input line for a portion of the line cycle, which inhibits the average energy transferred to the lamp load and hence, the output brightness. Both TRIAC dimmer and Yoswit smart universal dimmers operate by phase-cut dimming principle. However, they are very different in design. Traditional TRIAC dimmers operate on leading (forward) phase-cutting methodology which are designed for Incandescent and Halogen bulbs, using them for LED dimming have proven to be problematic as experienced by many installers. For more technical details, please expand to read the following article:

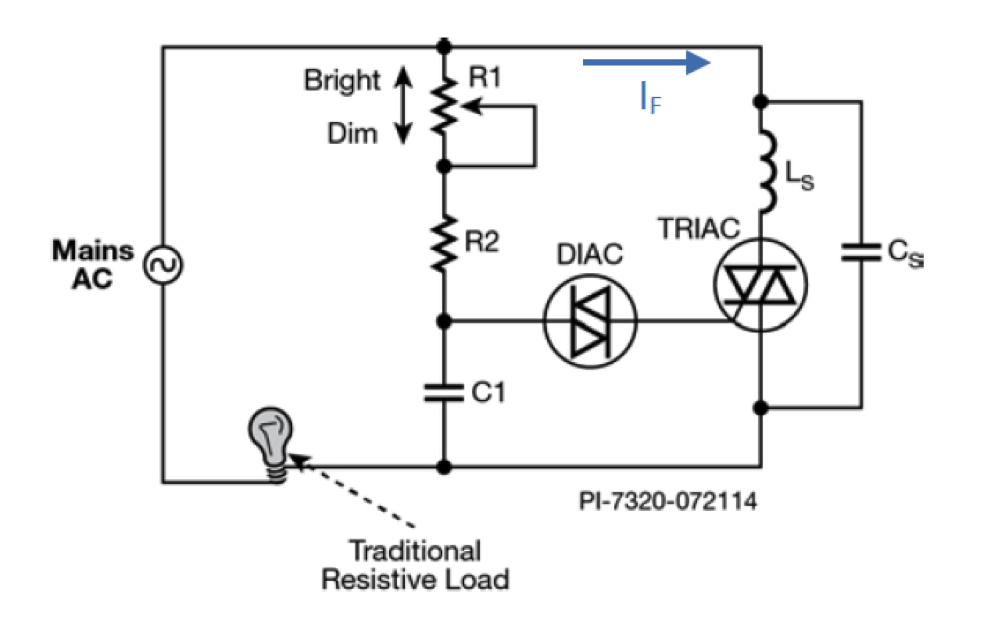

Figure 1. Simplified schematic of a leading-edge phase-cut dimmer (Including transient and surge suppression elements LS and CS)

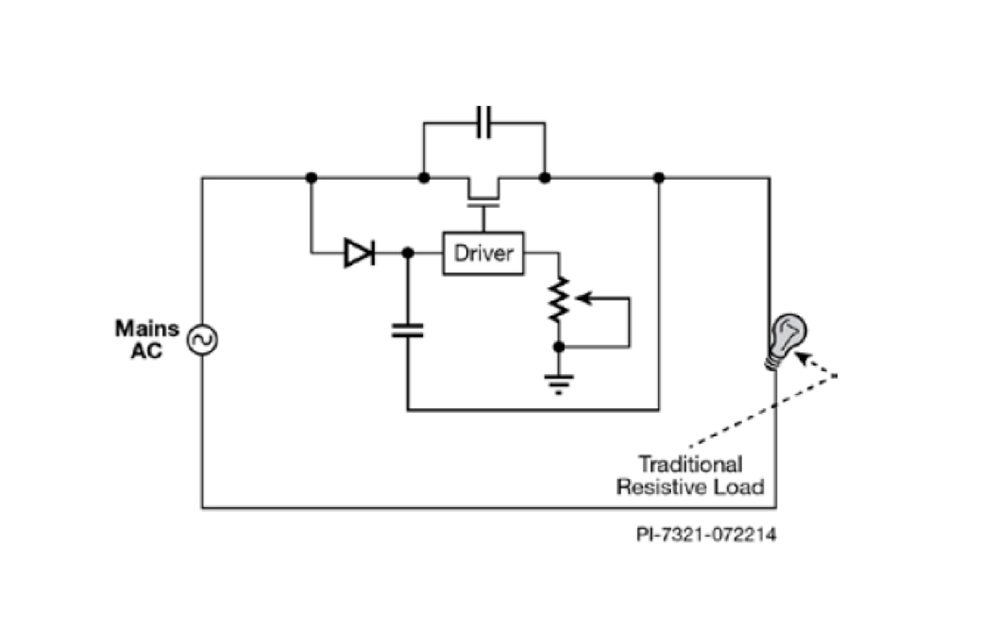

Figure 1. Simplified schematic of a leading-edge phase-cut dimmer (Including transient and surge suppression elements LS and CS) Figure 2. Simplified schematic of a trailing-edge, phase-cut dimmer

Figure 2. Simplified schematic of a trailing-edge, phase-cut dimmerIn leading-edge phase-cut dimmers, the switching element is typically a TRIAC. Unlike BJTs or MOSFETs the TRIAC will latch-on once it is energized (after forward current exceeds latching current). It will continue to conduct until the forward current drops below a threshold (holding current). The TRIAC is protected against input voltage surges by a bypass capacitor CS and from high transient currents at switch-on by a series inductance (LS). The installed base of TRIAC dimmers in use today are designed to work with an almost ideal resistance (an incandescent bulb). The bulb presents a very-low impedance during turn-on, latching the TRIAC (IF>>IL) and once in conduction allows current to flow to zero crossing which holds the TRIAC in conduction (IF > IH) for almost the whole AC half-cycle. With no capacitive or inductive elements, the incandescent bulb does oscillate when presented with the voltage step of a dimmed AC sine wave. Because the TRIAC-dimmer/incandescent-bulb interface is not sensitive to the LS and CS values, the values of these components are not constrained and vary significantly between different leading-edge dimmer designs.

At turn-on, an LED load presents relatively high impedance, so input current may not be sufficient to latch the TRIAC dimmer. In order to insure that IL is achieved, a bleeder circuit is typically added to the LED driver input stage. In the simplest form, the bleeder is a simple RC combination that insures a pulse of current when the input voltage is applied.

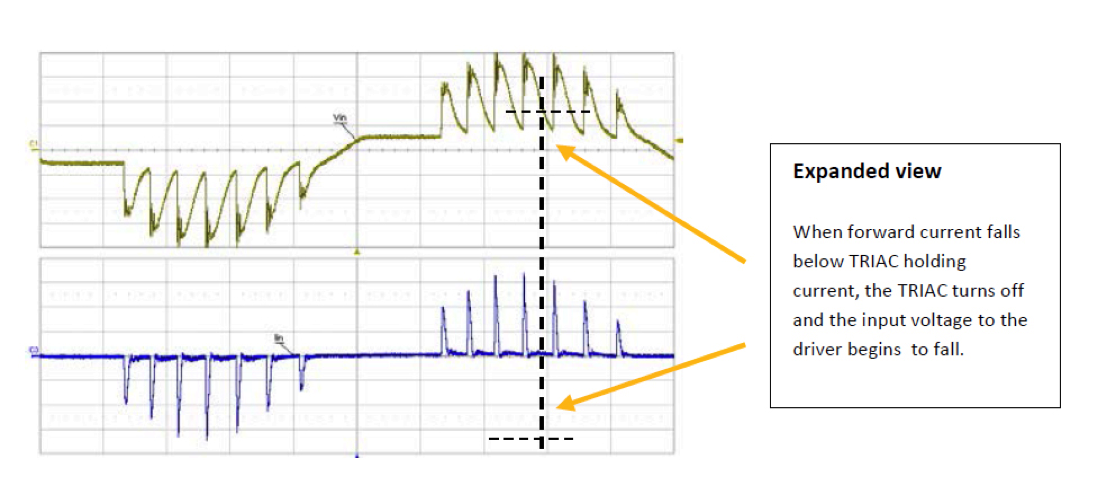

An LED lamp load does not exhibit incandescent-like pure resistance, and so, when presented with a step voltage the EMI filter and the bulk capacitance of the switching stage will cause an oscillation in the input current (IF) (see figure 3). The amplitude of the load ring is modulated by the surge protection capacitor CS, making the amplitude of the oscillation dependent on dimmer type.

Figure 3. Typical input current waveform for a power-factor-corrected dimmable bulb showing the oscillation caused by input current dropping below IH

Figure 3. Typical input current waveform for a power-factor-corrected dimmable bulb showing the oscillation caused by input current dropping below IHTo reduce the ring, a damper circuit is added – in its simplest form a series resistance to reduce the amplitude of oscillation at the expense of reduced efficiency (and therefore more heat for the LED bulb enclosure to manage). The LED Bulb designer must add the smallest amount of damping impedance at the input stage of the LED that will allow the LED bulb to remain above the minimum holding current. Different leading-edge dimmers have different values for CS and LS which act to modify the current ring on the TRIAC. The TRIAC in each dimmer type will see more ringing than would be seen at the bulb due to LS. The designer must allow sufficient margin (give up efficiency) in the damper circuit to work with as many dimmers as practicable.

To further enhance damping, a bleeder is needed to compensate for, or mask the ringing below, the holding current. A simple RC bleeder is used across the input line or after the bridge rectifier. The bleeder is optimized with respect to the power rating of the LED driver. For lower power LED lamps higher bleed is required.

Trailing-Edge Dimmers Present A Different Set Of ProblemsThe input voltage waveform from a trailing-edge dimmer is sinusoidal at the start of each half-line cycle. The MOSFET switch is driven by a controller which continually energizes the gate, making the dimmer less susceptible to current ringing.

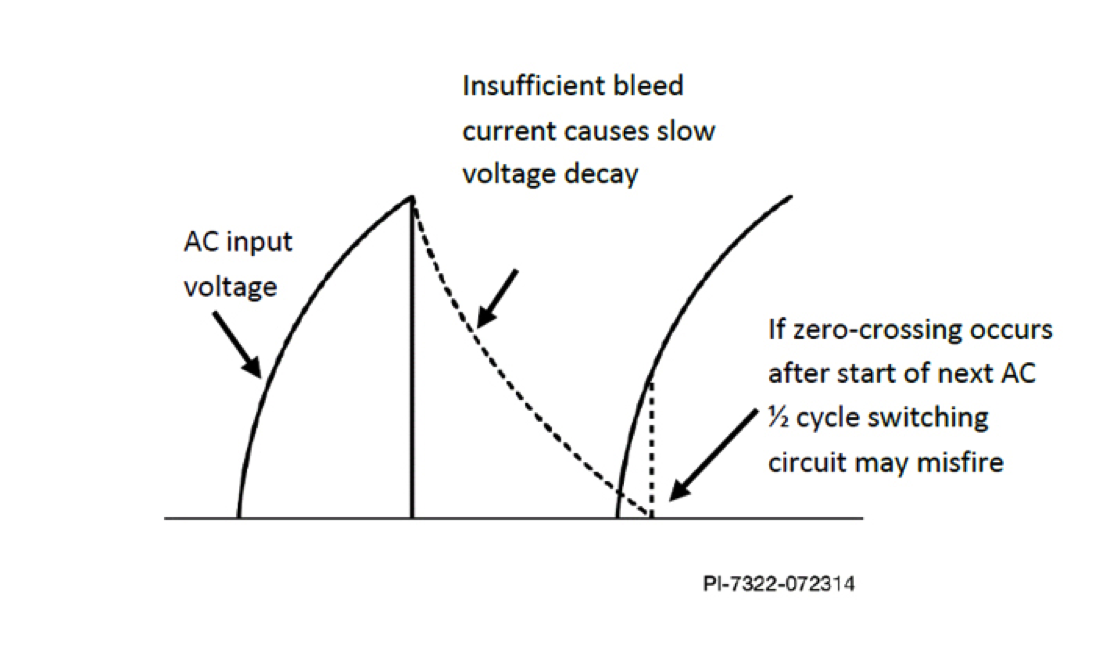

However, the power supply in the LED will present a high impedance to the dimmer when the MOSFET switch is opened to cut power delivery. Trailing-edge dimmers require the input voltage of the LED driver to fall to zero each half-cycle to enable the dimmer controller to energize its own supply rails. This ensures that the zero-crossing detector will turn on the switch at the beginning of the next voltage half-line cycle. If there is insufficient impedance to bleed down the dimmers output voltage before the next AC cycle begins, then the dimmer may misfire causing shimmer and flicker.

Figure 4. For a trailing-edge dimmer if insufficient current is drawn to force a zero-crossing before the next half-line cycle, the dimmer may misfire, causing shimmer or flicker

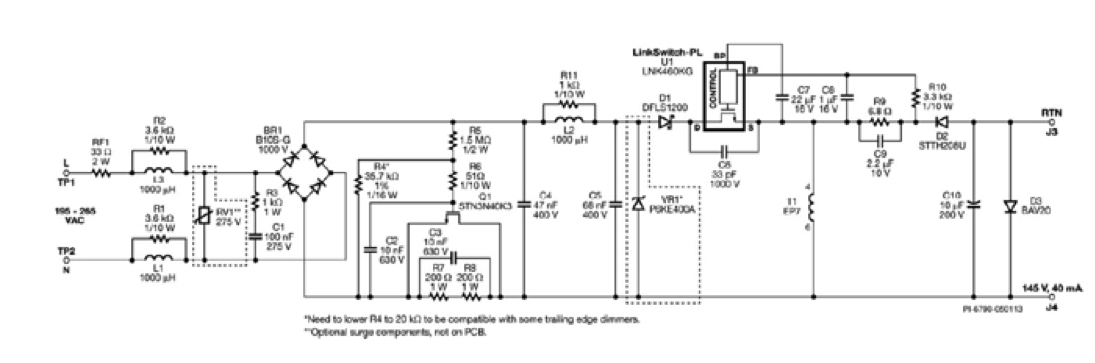

Figure 4. For a trailing-edge dimmer if insufficient current is drawn to force a zero-crossing before the next half-line cycle, the dimmer may misfire, causing shimmer or flickerBuck converters in particular have challenges when supporting trailing-edge dimmers. Buck converters are very popular for LED lamp drivers due to their high efficiency and low component count. For a buck topology, when the input voltage falls below the output voltage, the switching circuit cannot draw any power from the AC rail (and is therefore unable to bleed down the switch voltage). In contrast, buck-boost, tapped-buck and flyback converters can draw current for the entire switching cycle. For this reason, buck-boost converters and tapped-buck drivers with ICS, which switch through the whole line cycle as the LYTSwitch-4 from Power Integrations, can pull down the dimmer voltage after it turns off and are therefore better able to support trailing-edge dimmers.

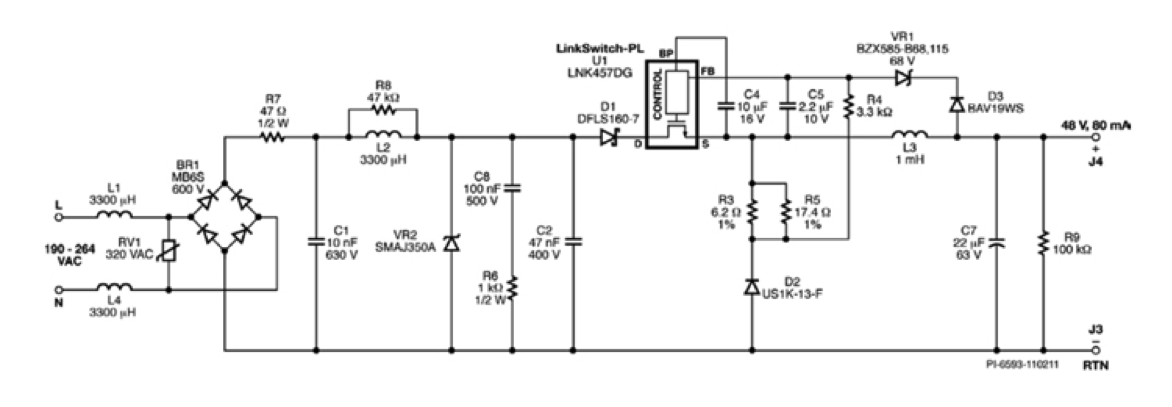

Figure 5a. Buck converter – Excellent with leading-edge dimmers. MOSFET D-S is reverse biased when the input voltage drops below ~48 V. The passive bleeder (C8/R6) is required to provide the low impedance path between line-neutral to force zero crossing of the input voltage to work with trailing-edge dimmers.

Figure 5a. Buck converter – Excellent with leading-edge dimmers. MOSFET D-S is reverse biased when the input voltage drops below ~48 V. The passive bleeder (C8/R6) is required to provide the low impedance path between line-neutral to force zero crossing of the input voltage to work with trailing-edge dimmers. Figure 5b. A buck-boost converter continues switching (provides a low impedance) to the input when the input voltage has fallen below output voltage, making this topology more suitable for trailing-edge dimmers

Figure 5b. A buck-boost converter continues switching (provides a low impedance) to the input when the input voltage has fallen below output voltage, making this topology more suitable for trailing-edge dimmers- Sources: Ledjournal

Leading Edge dimmers are typically lower cost and so are more widely used whereas Trailing Edge dimmers exhibit lower EMI and are preferred in some markets (notably Europe) and noise sensitive environments. That-being-said, it is unlikely that the average consumer will know whether their fixture is controlled by a leading-edge or a trailing-edge dimmer, and so it is important that LED replacement bulbs work with both types. The Yoswit smart dimmers support both Leading Edge and Trailing Edge dimming and can be switched case by case when connecting to different types of lamps through the app.

Deep Dimming

The minimum (and maximum) output light (Dimming Range) that can be delivered by the lamp when connected to a dimmer is an important characteristic for LED light bulbs. For deep dimming, a key dimmer performance indicator is the Minimum-Load-Required by the dimmer itself. As LEDs are very sensitive to the changes of the driving current from the driver, which ultimately is powered through the dimmer, very stable system performance by both the dimmer and the driver at low brightness level (when the current is already very small) is the key to project success. For more technical details, please expand to read the following article:

Read More In Technical Explanation:The typical dimming range requirement for leading-edge TRIAC dimmers is a 10:1 current step; for trailing edge dimmers the figure is above 5:1. To understand what controls dimming range and why the accepted performance for leading-edge and trailing-edge dimmers is different, it is necessary to understand how minimum output current is achieved in a phase-cut dimmer.

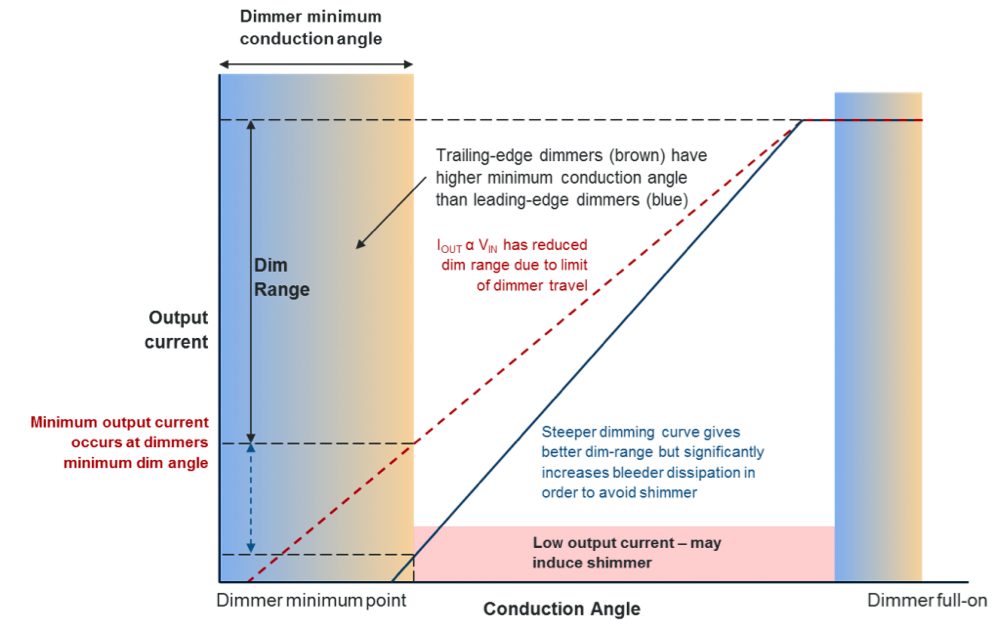

Figure 1. The effect of TRIAC dimming angle on LED driver output current

Figure 1. The effect of TRIAC dimming angle on LED driver output currentTrailing-edge dimmers use internal logic circuitry to control the dimming angle which requires power. This power is delivered to the driver when the TRIAC is turned-off (not delivering power to the lamp). To ensure this happens, trailing-edge dimmers tend to have higher dimming angle than equivalent leading-edge types. Typically this was not a problem with incandescent bulbs because their light output changes exponentially with power at low brightness levels (the bulb gives very little light output at low conduction angles) which means low brightness occurs significantly above the limit the power storage requirement imposes.

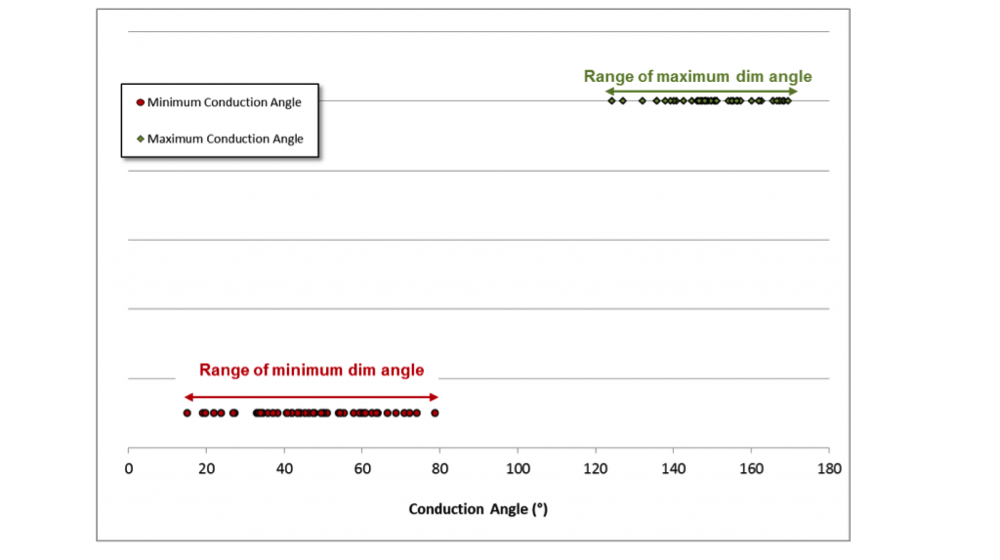

Figure 2. Maximum and minimum dimming angles for highline dimmers (Source: Power Integrations) – The range of maximum and minimum dimming angles makes wide dimming range challenging

Figure 2. Maximum and minimum dimming angles for highline dimmers (Source: Power Integrations) – The range of maximum and minimum dimming angles makes wide dimming range challengingTrailing-edge dimmers use internal logic circuitry to control the dimming angle which requires power. This power is delivered to the driver when the TRIAC is turned-off (not delivering power to the lamp). To ensure this happens, trailing-edge dimmers tend to have higher dimming angle than equivalent leading-edge types. Typically this was not a problem with incandescent bulbs because their light output changes exponentially with power at low brightness levels (the bulb gives very little light output at low conduction angles) which means low brightness occurs significantly above the limit the power storage requirement imposes.

The red trace in figure one shows an LED driver output current that is directly proportional to the conduction angle. The LED load takes a high load current even at relatively low conduction angles, but does not reduce current sufficiently by the time the minimum conduction range for TRIAC dimmer is reached. The high load current delivered using this approach means that TRIACS will see high holding currents, reducing the likelihood of shimmer or flicker.

The designer can elect to increase the dimming-slope of the LED driver to arrive at a lower output current at a higher dimming angle (blue trace in figure 1). This allows the bulb to dim to a lower brightness but risks causing shimmering and/or flickering as the load current drops. In a practical design this means that a significant amount of extra power must be drawn by a bleed circuit to keep the TRIAC from misfiring (this region is shown in red area in figure 1). This reduces driver efficiency making the need for heat sinking or potting materials more likely in the final design.

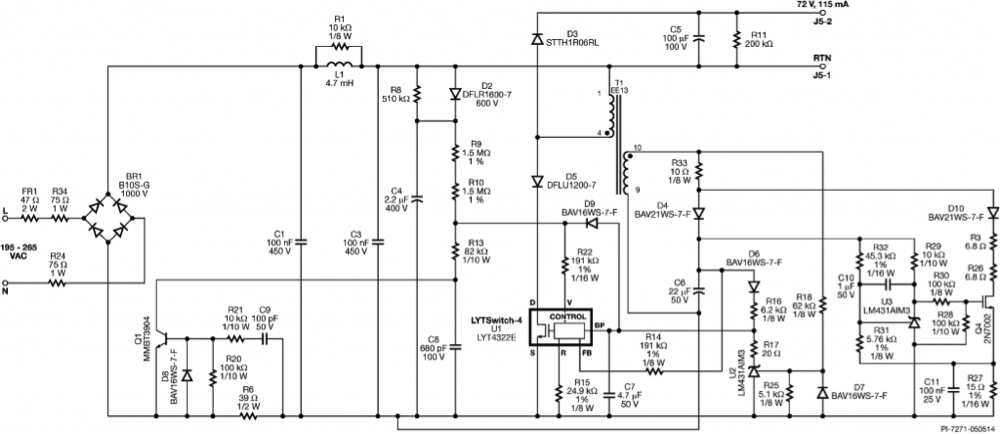

An alternative approach is to employ an adaptive bleeder circuit such as shown in the driver in figure 3. The bleeder circuit draws more current in deep dimming to compensate for the reduced output current but preventing excess heating at full brightness

Figure 3. Dimmable bulb driver with smart (lossless) bleeder function. The driver also shuts off at very low output current (deep dimming) to reduce the risk of TRIAC dimmer misfiring and causing shimmer.

Figure 3. Dimmable bulb driver with smart (lossless) bleeder function. The driver also shuts off at very low output current (deep dimming) to reduce the risk of TRIAC dimmer misfiring and causing shimmer.Dimming range, like so many of the design considerations for a TRIAC dimmable LED driver, cannot be considered in isolation. A design requirement that pushes for excellent dimmer compatibility and extended dimming range will (with presently available driver circuitry) lead to increased solution cost.

- Sources: Ledjournal

The deep dimming requires high quality dimmer and high quality dimmable driver inside the LED lamp. Yoswit provides the Industry Highest Level of compatibility to support up to 97% deep dimming level (i.e. 5v-220v, 97.7% / 4.5v-120v, 96.25%). In addition, as there are numerous LED driver manufacturers in the market and the performance of dimming of these drivers are various a lot (some may be dimmed to only 45%), the Yoswit smart dimmer switch provides the flexibility for customer to set the minimum level through our app to fix the driver acceptable dimming range to achieve flicker-free LED dimming.

2-in-1 Triac & 0/1-10v Dimming

0/1-10v dimming (Read more) is another common approach in a large area or high power consumption requirement LED strip light dimming application. As a single 0/1-10V control can connect multiple LED drivers in parallel, more and more installers and lighting suppliers are now choosing the technology not only for business use, but also for consumer market. However, most of the consumers don’t know which type of dimmer controller is to buy. The Yoswit smart dimmer switch is the World’s Only Switch in the market allow you to use with either Triac dimming mode or 0/1-10v dimming mode, providing you the highest flexibility for you to choose the favor driver solution.

Sync Dimmer Brightness On Multiple Switches

Unlike the traditional manual dimmer, the Yoswit smart dimmer switch provides the app interface to display the output level on the screen for each of the switch. The output of the switch can be set as a scene and synchronized the lamp brightness on multiple switches with just a click.

Specialized in Smart Light Switches